As the world transitions into the fourth industrial revolution—commonly known as Industry 4.0—India stands at a pivotal point in redefining its manufacturing landscape. Industry 4.0 is characterized by the fusion of technologies such as artificial intelligence (AI), machine learning, robotics, big data, cyber-physical systems, and the Internet of Things (IoT), all of which are transforming how factories operate and how products are made.

At the heart of this transformation lies a critical question: Are our engineers ready for this change?

The Industry 4.0 Shift: More Than Just Automation

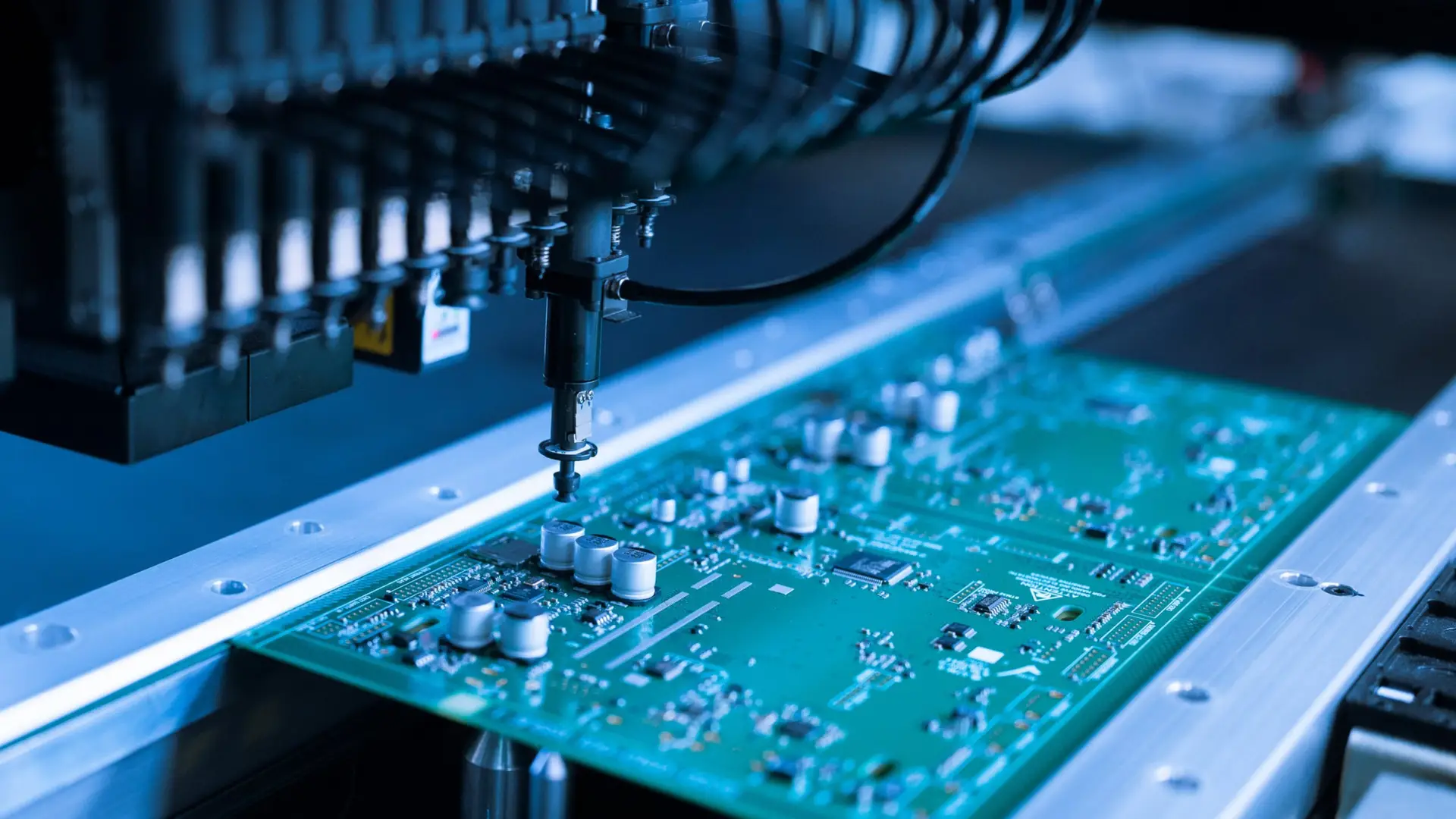

Unlike the previous industrial revolutions, which were defined by mechanization, mass production, and computerization, Industry 4.0 brings intelligent, interconnected systems that require engineers to not only understand hardware but also be fluent in software, data, and systems integration. Machines are no longer just tools—they’re now decision-makers, connected to networks and capable of learning and adapting in real-time.

India, with its vast pool of engineering talent, is uniquely positioned to lead this shift—but only if the skill sets of its workforce align with the changing demands of the industry.

The Skills Gap in Traditional Engineering

For years, engineering education in India has focused on theory-heavy curricula with limited industry exposure. As a result, many graduates enter the job market lacking hands-on experience in real-world industrial environments, particularly those that now demand knowledge in digital manufacturing, AI/ML integration, cloud computing, automation, and predictive analytics.

According to industry leaders, this skills gap is a pressing challenge. Companies today need multi-disciplinary engineers who are not only strong in mechanical, electrical, or civil engineering basics but also equipped with data literacy, programming ability, and an understanding of smart systems.

Educational Transformation: Building Future-Ready Engineers

To bridge this gap, India’s educational institutions and industry stakeholders are rethinking how engineering is taught. Some of the key developments include:

- Revamped Curricula: Universities are integrating subjects like industrial IoT, robotics, digital twins, cybersecurity, and AI into traditional engineering programs.

- Industry-Academia Collaborations: Leading manufacturing firms are partnering with colleges to offer real-time industrial projects, internships, and joint research opportunities.

- Skill-Focused Certifications: Platforms like the National Skill Development Corporation (NSDC), AICTE, and various edtech players are providing specialized certifications that enhance employability in Industry 4.0 roles.

- Centers of Excellence (CoEs): Several institutions are setting up labs and innovation hubs where students can work on real-world smart manufacturing problems using cutting-edge tools and technologies.

Rise of Smart Manufacturing Talent in India

The result of these efforts is a new generation of “smart engineers”—professionals who are not just technically proficient but also digitally empowered, collaborative, and innovation-driven.

From automotive and aerospace to pharmaceuticals and electronics, Indian manufacturing is seeing increased adoption of automation and data-led processes. Engineers who understand how to design systems that interact with machines and analyze production data are becoming invaluable assets.

Moreover, India’s role in the global supply chain is expanding. As multinational companies look to diversify manufacturing bases, India is emerging as an attractive destination, thanks in part to its growing base of future-ready engineers.

Reimagining Engineering for Industry 4.0: The Rise of India’s Smart Manufacturing Talent

As the world transitions into the fourth industrial revolution—commonly known as Industry 4.0—India stands at a pivotal point in redefining its manufacturing landscape. Industry 4.0 is characterized by the fusion of technologies such as artificial intelligence (AI), machine learning, robotics, big data, cyber-physical systems, and the Internet of Things (IoT), all of which are transforming how factories operate and how products are made.

At the heart of this transformation lies a critical question: Are our engineers ready for this change?

The Industry 4.0 Shift: More Than Just Automation

Unlike the previous industrial revolutions, which were defined by mechanization, mass production, and computerization, Industry 4.0 brings intelligent, interconnected systems that require engineers to not only understand hardware but also be fluent in software, data, and systems integration. Machines are no longer just tools—they’re now decision-makers, connected to networks and capable of learning and adapting in real-time.

India, with its vast pool of engineering talent, is uniquely positioned to lead this shift—but only if the skill sets of its workforce align with the changing demands of the industry.

The Skills Gap in Traditional Engineering

For years, engineering education in India has focused on theory-heavy curricula with limited industry exposure. As a result, many graduates enter the job market lacking hands-on experience in real-world industrial environments, particularly those that now demand knowledge in digital manufacturing, AI/ML integration, cloud computing, automation, and predictive analytics.

According to industry leaders, this skills gap is a pressing challenge. Companies today need multi-disciplinary engineers who are not only strong in mechanical, electrical, or civil engineering basics but also equipped with data literacy, programming ability, and an understanding of smart systems.

Educational Transformation: Building Future-Ready Engineers

To bridge this gap, India’s educational institutions and industry stakeholders are rethinking how engineering is taught. Some of the key developments include:

- Revamped Curricula: Universities are integrating subjects like industrial IoT, robotics, digital twins, cybersecurity, and AI into traditional engineering programs.

- Industry-Academia Collaborations: Leading manufacturing firms are partnering with colleges to offer real-time industrial projects, internships, and joint research opportunities.

- Skill-Focused Certifications: Platforms like the National Skill Development Corporation (NSDC), AICTE, and various edtech players are providing specialized certifications that enhance employability in Industry 4.0 roles.

- Centers of Excellence (CoEs): Several institutions are setting up labs and innovation hubs where students can work on real-world smart manufacturing problems using cutting-edge tools and technologies.

Rise of Smart Manufacturing Talent in India

The result of these efforts is a new generation of “smart engineers”—professionals who are not just technically proficient but also digitally empowered, collaborative, and innovation-driven.

From automotive and aerospace to pharmaceuticals and electronics, Indian manufacturing is seeing increased adoption of automation and data-led processes. Engineers who understand how to design systems that interact with machines and analyze production data are becoming invaluable assets.

Moreover, India’s role in the global supply chain is expanding. As multinational companies look to diversify manufacturing bases, India is emerging as an attractive destination, thanks in part to its growing base of future-ready engineers.